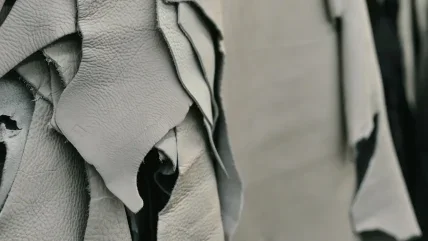

The global leather industry creates four billion pounds of scrap leather waste every year. Currently, that’s mainly sent to landfills or incinerated. As shareholders and governments push brands and other companies to be more sustainable, recycling that scrap can keep it out of landfill and give it new life – and new value.

Leather waste is not all created equally. “Some recycled leather is made from wet-blue scrap and some is made from tannery scrap, but production scrap is the hardest one because there is more of a risk for contamination by other materials,” says sustainability consultant Liz Alessi.

Despite the differences and challenges, Alessi says there are companies successfully turning these scraps – along with post-consumer leather waste – into new leather without adding plastic.

At the top of the list is Sustainable Composites, the company that has developed Enspire Leather. Founded in 2012, Sustainable Composites spent seven years on research and development to create the material that is a complement to, and not a replacement for, traditional hide leather.

Early projects that used wet-blue shavings were not successful. But, as they took in the feedback and once they developed the right product, it generated lots of interest. “We developed a proprietary way to grind the leather but preserve the leather fibres,” says chief technical officer Tom Tymon, who co-founded the company with chairman Frank Fox.

After grinding the scrap in a particular way, the process creates a sheet of leather that can meet almost all the specifications for traditional leather, Tymon says.

“If you look at our material under a microscope, and compare it to a piece of traditional leather, they look very, very similar. You can see the leather fibre structure in both,” says CEO Don Morrison.

Most importantly, Enspire Leather generates 75% less CO2 than an equal amount of new leather.

Actually, the company has three different products, Morrison explains. The first is their traditional Enspire leather, which is made from scrap waste recovered from the production of Wilson footballs. (The football might be casually called a pigskin, but it’s made from bovine leather.)

“We can’t get rid of all of the leather or all the fresh hides that go to the landfill or the incinerator, but we can slow it down, and slow down the rate of accumulating waste.”

Frank Fox, Sustainable Composites

The second product is made from cutting room scrap and the third uses deconstructed postconsumer scrap leather.

Whether or not Sustainable Composites can use a particular type of cutting room scrap depends on the type of scrap and the final application, Tymon explains. When a brand or other company wants to transform their leather scrap, they can send 50lb to Sustainable Composites for testing.

The lab processes the scrap and evaluates and checks its viability. Then, the brand can choose to explore using the scrap for a particular use and specify the desired properties. Then, the scrap is tested again, this time against those specifications. They can do a production trial and, if all goes well, the company can choose to move on to doing full production.

Even though Enspire is made entirely of leather fibres, it’s still a new material. “Some of the luxury brands are wrestling with how to use this new material. Does using recycled material enhance the perceived value of their brand or does it diminish it? If you ask younger customers, using recycled leather will enhance the value,” Morrison says.

Replacing plastics

While many alternative materials have come on the market, they don’t solve the issue of leather waste. Moreover, many seek to replace leather. Enspire leather needs traditional leather scrap as a starting material.

“I think it will replace the use of other things,” says Fox. “The industry now uses polyurethane splits – they want to get rid of them.” The films and coatings used on splits and other faux leathers are not conducive to recycling and Enspire can replace those. In recycling, “this is the only alternative that takes leather and gives back leather,” he says.

“We can’t get rid of all of the leather or all the fresh hides that go to the landfill or the incinerator, but we can slow it down, and slow down the rate of accumulating waste,” Fox explains.

Cost-wise, Morrison says that Enspire is competitive with other materials and is cheaper than virgin leather. Moreover, it has more green attributes than top grain leather and all the same physical attributes – except it provides better production yields because it doesn’t have flaws and comes on a uniform roll.

“In the fashion space, we work with everyone from super luxury at the highest levels of fashion all the way down to the biggest discount stores.”

Scott Kuhlman, Recircled

“We go to market trying to offer benefits to everyone in the chain,” says Fox. “For the purchasing agent, the price will be less. For the plant manager, he gets a better yield, and the marketing manager gets a new product with a great sustainability story.”

Post-consumer waste leather

When it comes to post-consumer leather waste, Sustainable Composites has partnered with Recircled, a US-based company that has pioneered a way to harvest leather and other materials from finished goods. The leather that Recircled reclaims from used fashion items – as well as unsold goods – is sent to Sustainable Composites to be recycled into new material.

In what the company calls “the infrastructure for fashion in the circular economy”, co-founder Scott Kuhlman says they break down footwear into parts, each of which has value. When it comes to the leather, “we harvest the biggest and best pieces and parts”.

In the early stages, Recircled initially disassembled items manually but is now automating the process, which will help lower the cost further. Another step “will be showing design teams ‘this is how we take a shoe apart, now design into that process so we can get 50% of the area of the shoe recovered at high value’,” Kuhlman explains.

After Recircled harvests the leather pieces, they are then sorted and graded. “Grade one can go to Sustainable Composites. Grade two can go to them also, but it will be a lower-value piece of recycled leather… it’s fine for interior pieces,” Kuhlman says.

He notes that they are developing markets in other industries that can use these materials, such as the furniture industry, where many models have a lot of hidden pieces and parts, for example.

“In the fashion space, we work with everyone from super luxury at the highest levels of fashion all the way down to the biggest discount stores,” Kuhlman explains. This is becoming more important as regions like the European Union and some US state are outlawing the destruction or disposal of shoes and clothing – whether it’s an unsold luxury handbag or a pair of mass market sneakers.

The quantities of merchandise can be staggering when looking at unsold goods along with discontinued, flawed and damaged items. This is especially true with goods that may have been stored for some time.

Recircled has two factory facilities, one in Cozad, Nebraska, and a second in Prato, Italy. Now, it is about to partner with a very large company and will be opening facilities throughout Asia and adding post-industrial waste recycling, which can process leather waste as well.

“We’re working with companies that are very unexpected. We had no idea that they use tremendous amounts of leather. It’s not that they’re going to get away from using hides at all. It’s more about how do they offset it and how can they use more,” he says.

Ultimately, it comes down to helping the leather industry, according to Sustainable Composites.

“Obviously, top grain leather is a great product, but it generates scrap. We want to help the leather industry by having a good product made from the scrap, and we think that over time there’s an opportunity for the leather industry and our product to replace some of the faux leathers and leather alternatives because of some of the issues with the use of synthetic material,” Tymon concludes.

Consumer leather in the circular economy

Leather recycling can be an eco-friendly practice that helps reduce waste and extend the lifespan of leather products:

- Reuse and repair: One of the simplest ways to recycle leather is to reuse it or repair leather items. This can involve repairing or altering leather garments, bags or shoes to give them a new life and prevent them from being discarded.

- Upcycling: Upcycling involves transforming old or unwanted leather items into new products with a higher value or purpose. For example, leather scraps can be repurposed into smaller accessories like wallets, keychains or jewelry.

- Leather recycling facilities: Specialised recycling facilities exist that collect and process leather waste. They may use mechanical or chemical processes to break down the leather into fibres or pulp, which can be used to make new leather products or non-leather materials.

- Composting: In some cases, leather scraps can be composted under specific conditions. Treated leather, which is free from harmful chemicals and additives, can be added to compost piles or facilities that process organic waste.

- Leather fibre recovery: Leather waste can be processed to extract fibres. These fibres can be mixed with other materials to create composite materials for various applications, such as insulation or padding.

- Donation and second-hand markets: Donating leather goods that are in good condition or selling them through second-hand markets is another way to recycle leather. Not all leather products can be easily recycled due to treatments, finishes or mixed materials. However, the recycling options mentioned above provide some sustainable alternatives to minimise leather waste and environmental impact.