3D Bio-Tissues (3DBT), a UK-based biotech start-up, has produced a lab-grown leather solution intended for use in the luxury goods market.

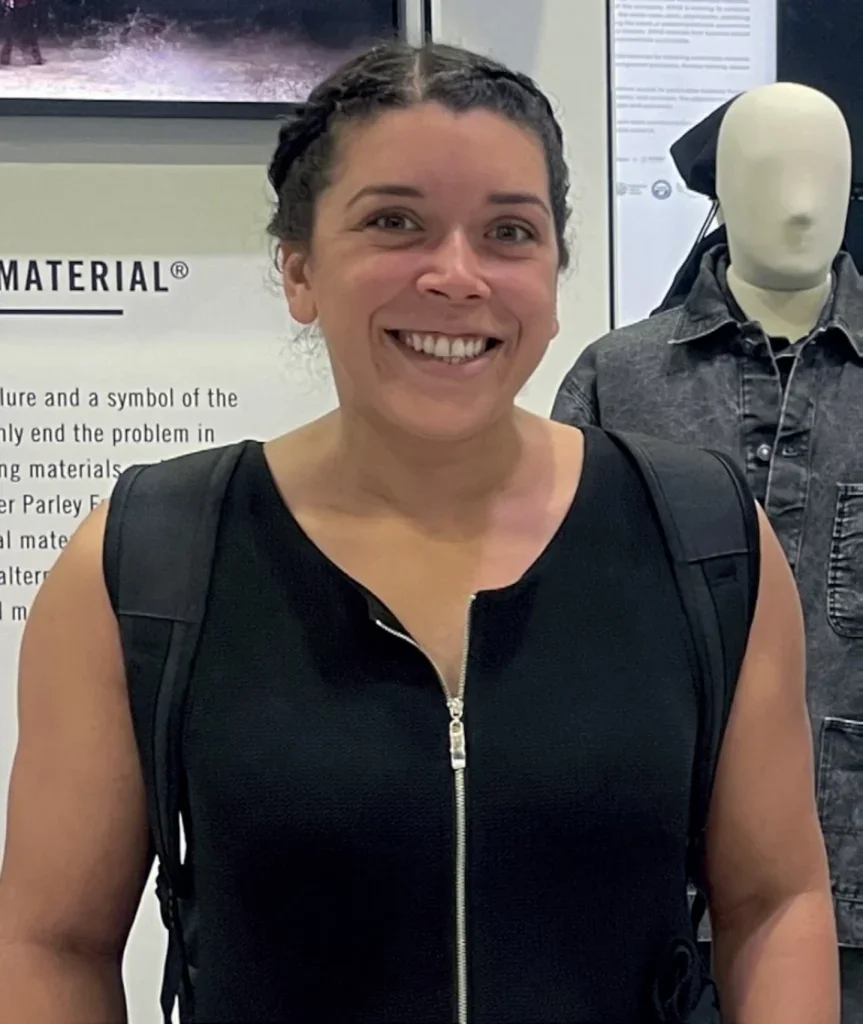

At the Future Fabrics Expo – a biotech fashion event held in London during the summer – the company unveiled bio-engineered samples it says are structurally and genetically identical to traditional leather.

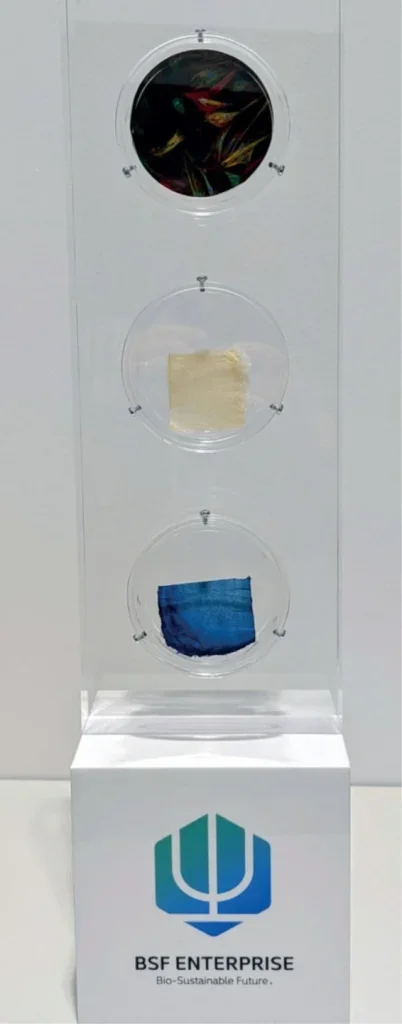

3DBT developed its skin, which took six weeks to grow in a lab, from cells isolated and collected from an adult female horse. It says its patented, serum-free and animal-free cell culture food supplement, City-mix, accelerated tissue production while reducing the cost of the production process.

According to the company, the product can be tanned using either traditional leather production processes or modern ecologically sensitive approaches, “resulting in a material as diverse in colour and appearance as classic leather”. Its skin and leather samples, it says, showcase the potential for new materials to have the same properties, composition and use of farm-based leather.

Tanning expertise for the project was provided by the University of Northampton. The project itself was funded by the UK Research and Innovation (UKRI) through Innovate UK with the support of co-funders, including the Scottish Funding Council, Welsh Government, Invest Northern Ireland, and the Department of Department for Business, Energy and Industrial Strategy (BEIS).

Speaking ahead of the Future Fabrics Expo event, senior research and development scientist at 3DBT, Dr Emily Telford, said: “We are really excited to be working with the University of Northampton to merge our innovative bioengineered skin with their vast knowledge of traditional leather processing techniques. We believe this initiative will address the growing demand for both conventional and alternative leathers as we strive for a more sustainable future.”

Northampton University’s Professor of Leather Science, Professor Will Wise, added: “This project has far-reaching scope – it will allow us to understand more about the fundamentals of collagen modification as well as developing a new biomaterial for commercial use. It is fantastic to be a part of it, and to work in close partnership with 3D-Biotissues to achieve their goals.”

Dr Che Connon, managing director of BSF Enterprise, a biotech investor that owns 3DBT, said: “We are delighted to present this highquality lab-grown leather, which we believe has the potential to meet the ever-increasing demand for animal-conscious alternative leather products. The product we have unveiled… demonstrates the potential of our tissue engineering technology in solving some of the fashion industry’s greatest issues and we look forward to engaging brands with our technology.”

Leather properties

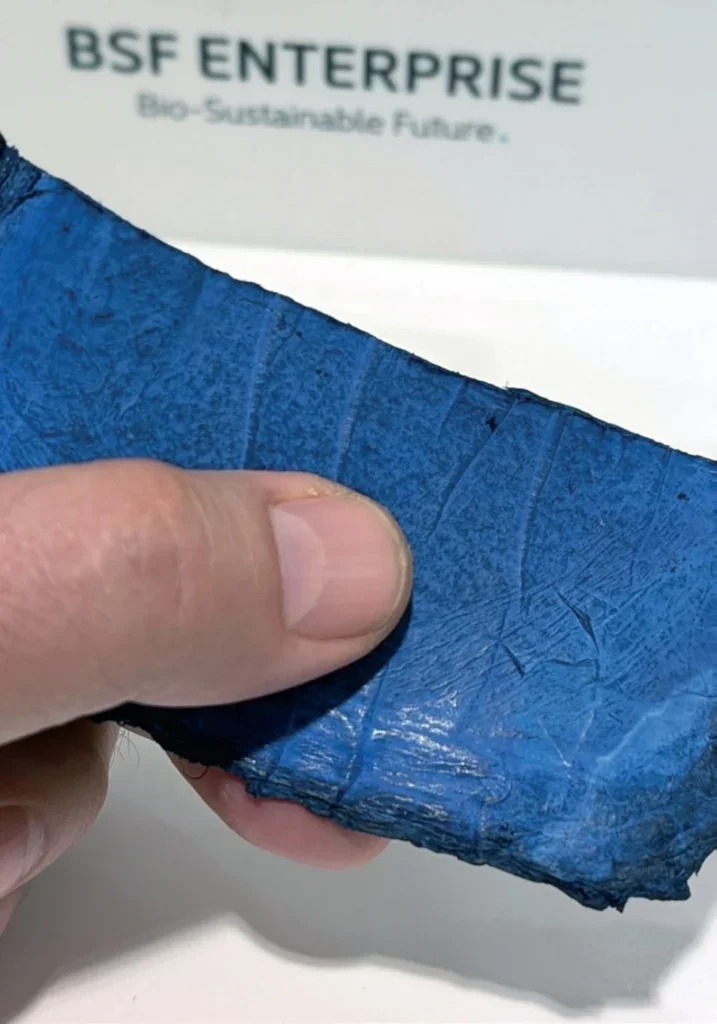

As with any leather alternative, the ultimate question is whether it displays the properties of traditional leather. Connon has no doubt that 3DBT’s product has the same characteristics. Having felt other leather alternatives, he believes that 3DBT’s solution compares favourably to them.

“It has a nice robustness to it,” he says. “It will wear the same as leather, it will have the same visual appeal, the patination, the way that it marks and the way that it ages – all of those things will be there as they are in traditional leather.”

Connon says that this is to be expected because the material originates from 100% animal tissue.

“If you start with the right material, then the process will result in leather. So it’s not surprising,” says Connon, who states that representatives from several leading luxury goods companies have also handled the 3DBT’s samples and agree with his assessment that it “feels like leather”. One collaborator, he adds, has also tanned, stitched and embossed it, and was pleased with the results.

3DBT claims that what sets its solution apart from other leather alternatives is that no additional supporting materials, such as plastics or cellulose, were used in the final product.

“The uniqueness is in the fact that it doesn’t contain any other scaffolding materials or any other backing materials, any structural materials,” says Connon. “There are other approaches to bio leather using a cellulose scaffold or some other synthetic material, which the cells can be seeded onto, but then… you’re left with a structural feeling of cellulose, for example – not the structural feel of leather, which is collagen and elastin. And so ours just contains collagen, elastin and extracellular matrix molecules, which are found in normal skin and leather.”

Aside from providing a solution to the ethical and sustainability questions that traditional leather has to contend with, lab-grown alternatives can overcome many of the limitations of farm-grown leather, 3DBT insists. Animal skins and hides are limited by the size, skin thickness, and life of that animal, leading to inconsistencies and imperfections in the final leather. In contrast, lab-grown leather production can be more consistent, featuring uniform composition and thickness, free of natural imperfections, and can be scaled to produce a larger material.

Similar to farm-grown leather, 3DBT’s labgrown material is also expected to be completely biodegradable in 10-50 years, which contrasts with polymer-based leather alternatives that can take over 500 years to decompose. There are also potential cost savings for tanneries, with lab-grown solutions not needing to go through the process of beaming.

Connon points to another advantage, saying that 3DBT’s product could “facilitate more environmentally sensitive tanning approaches”.

“Because we can rationally design the tissue [that is, create new molecules by leveraging an understanding of the principles and mechanisms that govern their behaviour] – the density of the collagen, for example – it could be feasible, if you had, say, a vegetable tanning solution that doesn’t totally terribly well with traditional skin, to optimise the production of our skins such that those vegetable tanning works better,” Connon explains.

Target market

3DBT is targeting the luxury goods sector because it believes that consumers, in particular the younger generations of buyer, “who have an interest in luxury goods are also very aware of the environment and animal welfare”, says Connon.

He also believes that due to the extra costs involved in producing lab-grown leather – at least initially until production scales up – that luxury goods is a market that can bear some increase in the cost of materials. Such considerations are a way off, however, due to Connon explaining that it will be “at least a couple of years” before 3DBT has a product that is commercially viable.

“The next stages,” he says, “once we get the partnerships in place, is scaling up the production.

“Strategic partnering is, I think, the way we’re going with what we’re offering. At BSF Enterprise we’re not looking to be a manufacturer of leather – we’re an industrial tissue engineering company. We are working with other people to bring it to market.”