So, the Ethiopian Government has decided to lift the export tax on pickled, wet-blue and crust leathers. That is a significant turnaround and one really wonders whom they listen to and who is advising the government.

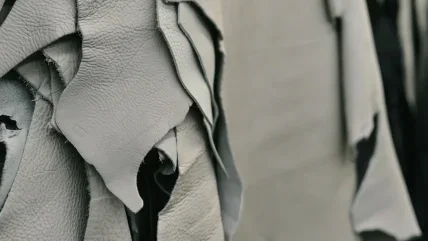

Readers will remember that I have frequently criticised the Ethiopian decision to impose a virtually impossible export tax on pickled, wet-blue and crust leathers. This export tax was imposed based on the so-called value addition strategy so strongly promoted by COMESA, NGOs and UN organisations. Ethiopian tanners had to scramble and make expensive debts to buy equipment and create pollution control first to be able to process pickled and wet-blue, which they exported successfully, into crust and then again when the export tax was also extended to crust in order to make finished leathers and leather goods.

You will also remember how the ALLPI, UN and NGOs celebrated this value addition effort of the government as their great achievement, even if the export figures increasingly demonstrated the disaster that they were causing to the Ethiopian leather industry. The visitor numbers at the Ethiopian leather fair steadily showed less interest from buyers, in spite of the organisers announcing 10,000-plus visitors each year, demonstrating that the chosen strategy was backfiring big time. Due to lack of interest, the AALF leather fair was integrated in 2019 into a commodity fair where leather represented less than 25% and textiles had the lion’s share. Leather visitors were estimated at 1,000, not the ‘usual’ 10,000.

Don’t celebrate too soon

Not too long ago, ALLPI published and celebrated with the usual fanfare their ‘new’ strategy for Ethiopia in which finished leather goods and footwear were the focus and objective. Huge earnings and employment figures were projected, none of which were realistic nor reachable. UNIDO prided itself on the great success of their support to carry the leather industry in Ethiopia to the level of finished products in various addresses in the opening ceremonies of the various Ethiopian leather fairs. These organisations should publicly apologise to the Ethiopian tanneries to whom they caused so much dismay and in many cases bankruptcy. The only protests came from me and I was criticised for my negative attitude towards the value addition process. Unfortunately, I was right.

Now, with the reversal of the export tax imposition Ethiopia is again making a serious mistake because they move from one extreme to the opposite. The tanneries will return to exporting wet-blue and crust, thus voiding all the investments made with blood, sweat and tears for finishing equipment and effluent treatment plants. There is no incentive anymore to produce finished leather and finished leather products, and the finance necessary to produce wet-blue or crust is much less than for a finished product.

What the government should have done is to bring the export tax on pickled and wet-blue leather to, let us say, 50% on crust, to 10–15% and zero export tax on finished leather, instituting an export incentive of 10–15% for finished leather products. That would have made the export of pickled and wet-blue leathers impossible, gently discouraged export of crust and encouraged finished leather and leather products.

So, who will benefit most from this new situation? The Chinese-owned tanneries, as they can export wetblue leathers to their Chinese base, something they have always wanted. Remember the Chinese were caught red-handed exporting containers of wet-blue, described as finished leathers. The government, with this incomplete decision, has simply facilitated the Chinese importers by letting the Ethiopian tanners do the dirty job and keep process pollution outside China.

Who is losing with this new situation? Those tanneries that have made large investments to makes finished leather and find themselves now with strong competition when buying raw materials by those that will export wet-blue. It’s incredible to see how things can be messed up by ignorance and incompetence, when in reality solutions can be found and kept simple.

Part two

The Italian Carabinieri of the anti-sophistication unit paid a surprise visit to a family business in the area of Naples to check on the compliance of their cafeteria with hygienic legislation requirements. Just to begin with, they found that the cafeteria did not exist. So, the Carabinieri checked and identified the personnel that was at work to ascertain whether they were regularly registered and, hence, if the company paid their social security and other labour-related taxes.

They found 35 workers, 14 of whom worked off the books. These 14 probably did not have the time to hide somewhere, so they were caught. However, things didn’t add up as the company had a huge order book for some top international brands. Furthermore, the company had a consistent stock of leather and accessories, which all pointed at a much bigger production than 35 people could cope with.

So, the Carabinieri went on a mission and checked the premises out in detail for over six hours until they found a ‘mountain’ of leather by the door to a safe – the type you can find in a bank. In the safe they found 43 workers, among whom was a pregnant woman. These 43 had been in there for more than six hours, behind the safe door in a room without light, water or sanitary facilities. In short, the company had 78 workers, of which only 21 were officially on the books. All worked for nine hours per day and were paid €500 per month.

It has not yet been revealed which brands bought from this factory, so no finger-pointing, just a general revelation, and an understanding that definitely not all brands submit themselves to such low-level supply methods.

The owner of the factory defended himself, saying that if he did not sell the brands’ ordered products at a cut-throat price, the job would go to Chinese workers either in Italy or in China itself. He said that he had no choice. He was arrested for fraud, tax evasion, labour exploitation and kidnapping.

What is the morale of this?

Obviously, the fact that brands buy their manufactured products from outside suppliers is logical, even if there is now a trend that brands buy their own tanneries. What is not logical, is that brands accept, even encourage, negotiating rockbottom prices so that suppliers pay their workers a ‘hunger wage’ and that the brands sell their fashion products at thousands, tens of thousands and in some cases hundreds of thousands.

Any defence from brands that they did not know or were not aware of the dire circumstances in which the workers of this particular supplier worked is not credible. Brands inspect their leather suppliers on compliance with effluent treatment requirements, CSR, present (uncoordinated) lists of restricted substances and hence an oversight of labour conditions in the factory of their suppliers is simply not possible. Like they inspect tanneries, it is more than plausible or logical that they also visit the factories that produce their products.

The Carabinieri told a newspaper that reported on the raid that this was certainly not an isolated case. There are tens, if not hundreds of this type of situations, particularly in the southern part of Italy, where poverty forces people to submit themselves to the exploitation of unscrupulous employers and buyers. Very sad.